this is because it is a zero ohm resistor. yes, zero. but wait--you say--isn't that just a wire?

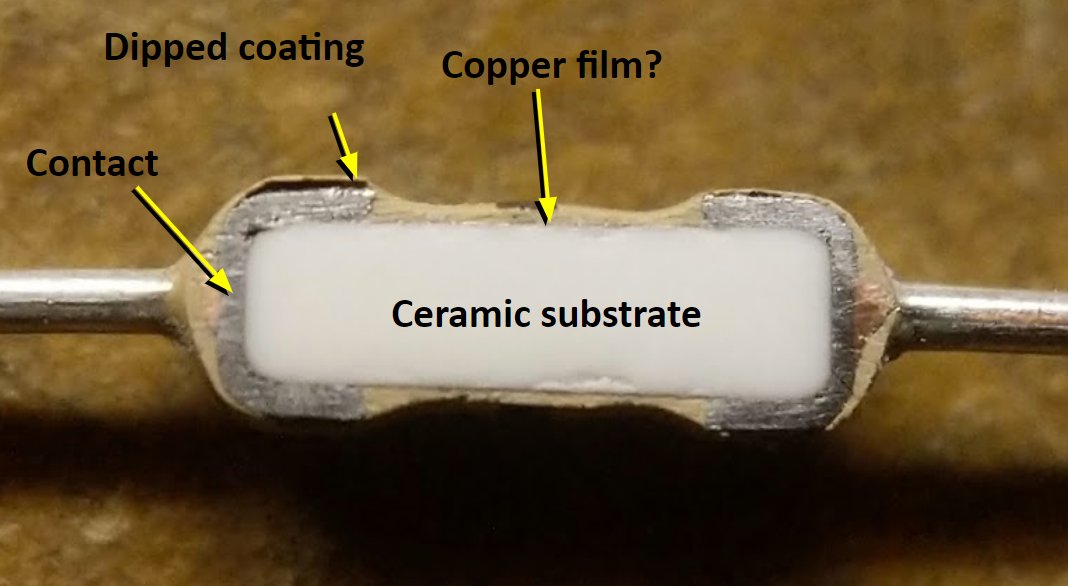

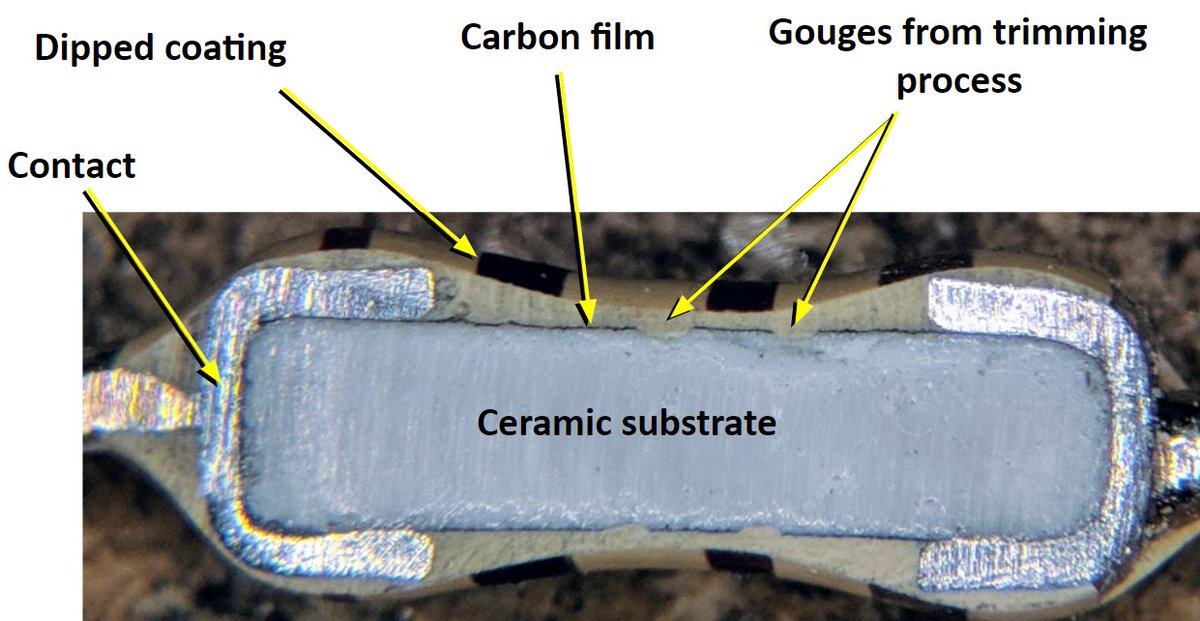

i removed the dipped coating on one of these so you can see that it's not carbon film. it looks like copper to me.

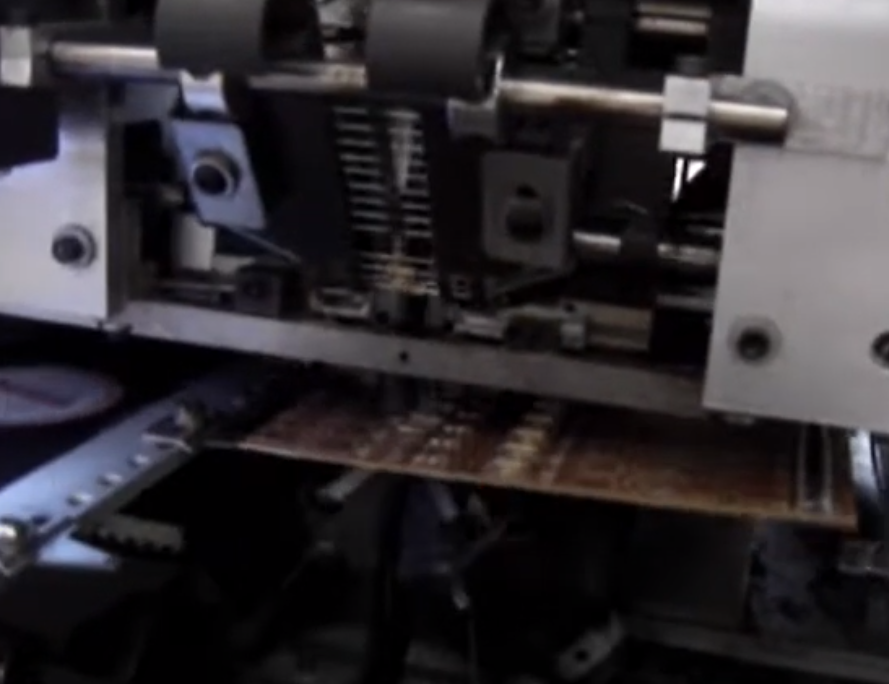

so why would you use one of these instead of, you know, just a wire? well, a zero ohm resistor can be installed by one of these machines, which can also handle diodes, certain capacitors, resistors, and other axial components. many of these machines test the parts too!

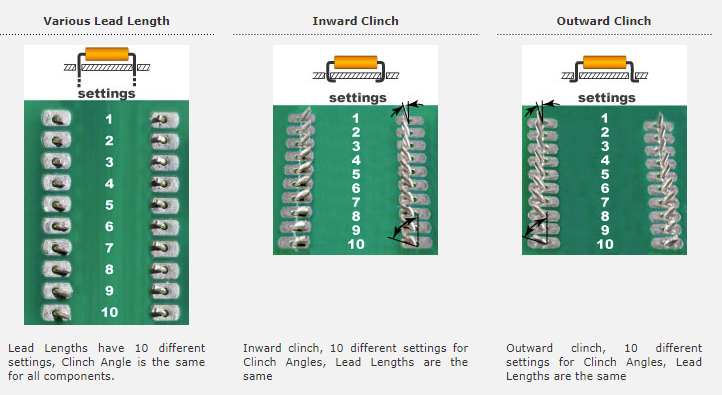

the machines also have all sorts of fun settings. after installing the part they even bend the leads afterwards to lock them in place before soldering.

and yes, they have wire jumper machines, but those are typically only found on single-sided PCB lines.

so if you need a wire jumper and your production line doesn't support them, then use a zero ohm resistor!

or maybe you have an assembly option (aka a stuffing option) where sometimes you need to change the value of a resistor, perhaps to zero ohms. then you use one of these.

i use these all the time in designs for work. they're great for things like UART RX and TX lines so you can fix a board with a simple change in the bill of materials. not that i'd ever accidentally swap RX and TX...

also, if you make the joke "1% or 5%? huehuehue" i will block you so fast

and no, the 0 ohm resistor is not made of a superconductor. it has a small amount of resistance.

Read on Twitter

Read on Twitter